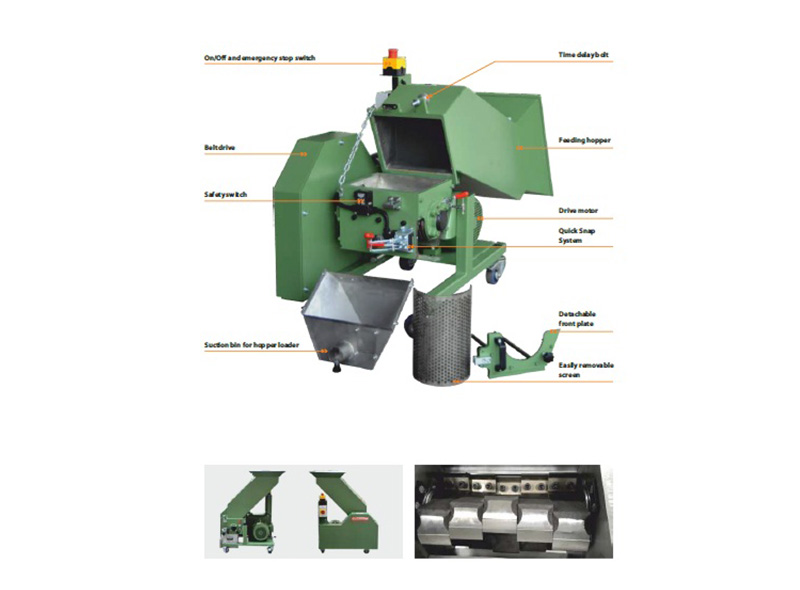

FUNCTION AND ADVANTAGES

CRUSHMASTER low-speed crushers are often used for the immediate recycling of runners, burrs and damaged parts.

Silent and Dust-free Operation Through Low Speed

Due to its low speed operation, it provides a quiet and dust-free working environment. Therefore, it can be used so as not to disturb the operator immediately next to the injection or blowing machines.

Powerful Rotor Structure

The diameter of the rotor shaft is designed to provide maximum efficiency during the crushing process and is secured by clutches on both sides. Thanks to the rotor blades arranged so as not to overlap, the engine torque is optimally distributed on the rotor. For this reason, it can break in the piece produced together with the runner.

Adjustable Blade Design

Crushmaster has specially designed the blades of its machines in order to eliminate the loss of time caused by adjustment during the blade change. Thanks to the curved structure of the blades, it can be mounted directly without any adjustment after sharpening.

Easy Response

The chamber of the crushers can be easily opened in a few steps without the need of using any wrench and the hinged structure allows the hopper to be tilted sideways and the blades can be easily interrupted. The sieve system on the underside of the machine can also be removed very easily. Therefore, the crusher can be cleaned very quickly when it is desired to break different colored material.

Low or High Mobility

In the low mobile construction system, the breaking chamber under the machine has a volume of 5 liters. By absorbing the suction probe in the crushing chamber, the crushed material can be used immediately by feeding it into the injection or blow molding machine.

In the high mobile construction system, the crushing chamber under the machine has a large volume of 20 liters. Thus, the cleaning of the crushed material reservoir can be carried out for longer periods.

High Safety

Thanks to the electrical switch system, the machine is not running when the crushing chamber or sieve system is open, thus providing a safe intervention environment for the operator.

-

Low-Purpose Machine Bereakers

-