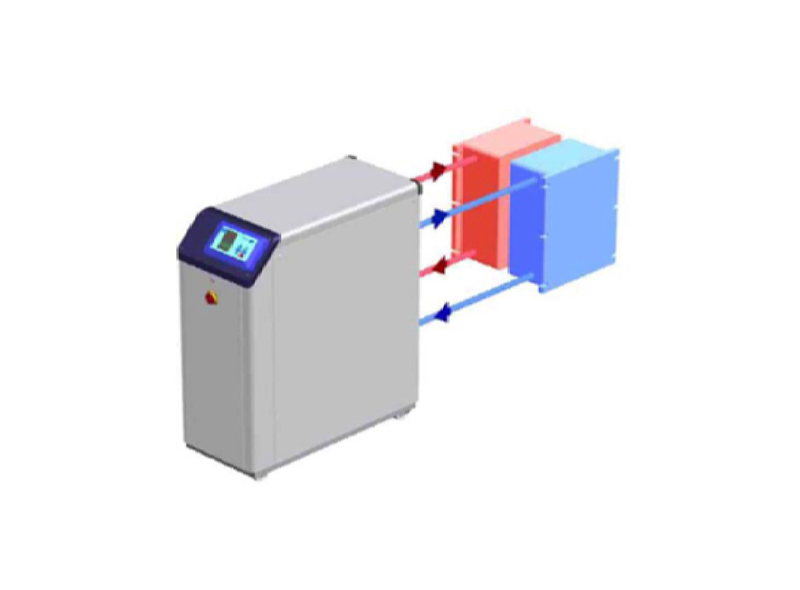

MICROGEL units are precision cooling and heating devices specially designed for molds. MICROGEL DUO units have dual water outlets. The flow rate, pressure and temperature (-5 ° C / +90 ° C) of each water outlet can be set separately.

In this way, an increase in production capacity and improvement in product quality are observed.

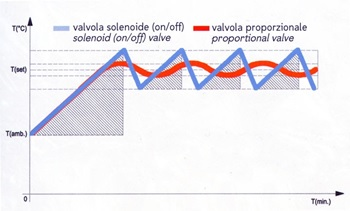

It has a proportional motorized valve system which belongs to Frigel. Proportional motorized valve system provides very accurate temperature control in + / - 0,3 ° C.

When the molds are cooled with the central chiller, the chiller will have to work even if 1 injection machine will work. However, when the molds are cooled with MICROGEL units, only the cooler of the running machine will work. This will save additional energy.

In the event of any failure, the production is not fully affected, only the production of that injection machine stops.

Since the desired temperature between -5 / + 90 C will be possible, there will be no need for additional thermoregulators.

Since the MICROGEL unit is installed next to the machine, it is possible to intervene immediately. Since the unit is wheeled, it can be easily transported to the required mold.

When the temperature drops in winter, the water temperature from your existing cooling system will decrease. If the incoming water temperature is sufficient for the mold, the compressors of the MICROGEL units will be disabled automatically. This will save you a lot of energy. Considering that the required cold water temperature in your molds is 15 ºC, the compressors of MICROGEL units will not operate (FREE COOLING) and will cool with external water if the outside water temperature is 15ºC and below. This will save you additional energy.