FUNCTION AND ADVANTAGES

TURBOGEL units are precision heat control devices specially designed for molds. TURBOGEL DUO units have double water outlets. The flow rate, pressure and temperature of each water outlet can be adjusted separately. The models are available for working at +90 C, + 140 ° C and + 160 ° C.

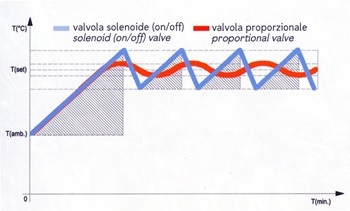

It has a proportional motorized valve system which belongs to Frigel. Proportional motorized valve system provides very sensitive temperature control in + / - 0,5 ° C and also decreases energy consumption. It takes the cold water required to balance the heat at minimum levels and ensures that the heater resistance is switched on and off for very short periods. Thus, energy savings of around 85% are achieved. In the units with solenoid valve system, the solenoid valve is open and close because it works more than the need of the device and it cannot perform sensitive temperature control. In addition, the resistance must be activated for a longer period in order to bring it to the same temperature. The table regarding the energy comparison of the motorized valve and the solenoid valve system is presented below.

The ones up to +90 ° C have a cooling system. In standard mold heaters, there are plate heat exchangers in the device. While the water is circulated in the primary circuit of the heat exchanger, the cold water circulation connected to the device is provided from the secondary circuit. In FRIGEL's TURBOGEL units, chiller water can be taken directly from the system by means of a motorized valve and can be mixed directly with the mold water. Thus, the cooling capacity of TURBOGEL units is much higher than that of standard mold heaters.

It works with SU. Water is one of the highest liquid heat transfer materials in nature. The heat conduction coefficient of the water is 1 kcal / kgºC and the heat conduction coefficient of the oil is 0,4 kcal / kgºC. This means that the cooling capacity of the device is 2.5 times higher than the OILED devices. In parallel with this, the electricity consumption of the OIL appliances will be higher.

It is controlled and controlled by an advanced microprocessor. Each page has an alphanumeric display of 80 characters. The temperature of the leaving water, the water temperature around the resistance (in this way the efficiency of the resistance), the outlet pressure, can be seen. The history of the backward alarm is available. The operating times of materials such as pumps, resistors can be seen on the screen. Thus, the device can be intervened without failure.

TURBOGEL model devices automatically receive the amount of water required for the mold in the first run. It also automatically removes air from the water pipes in the mold and into the mold. In the case of a lack of water in the mold, it automatically completes taking the water from the installation.

The microprocessor can be connected to the thermocouple when necessary, and the temperature of the mold plate or other area can be seen on the screen.

It is made of stainless steel.

It has a tropical engine.

There is a by-pass valve to balance the water pressure to the mold.

Maintenance-free. Manufactured from very high resistance to corrosion. Easily portable thanks to its wheels. The cooling water inlet has filter and relief valves.